Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

Basic Information

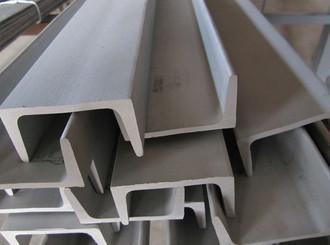

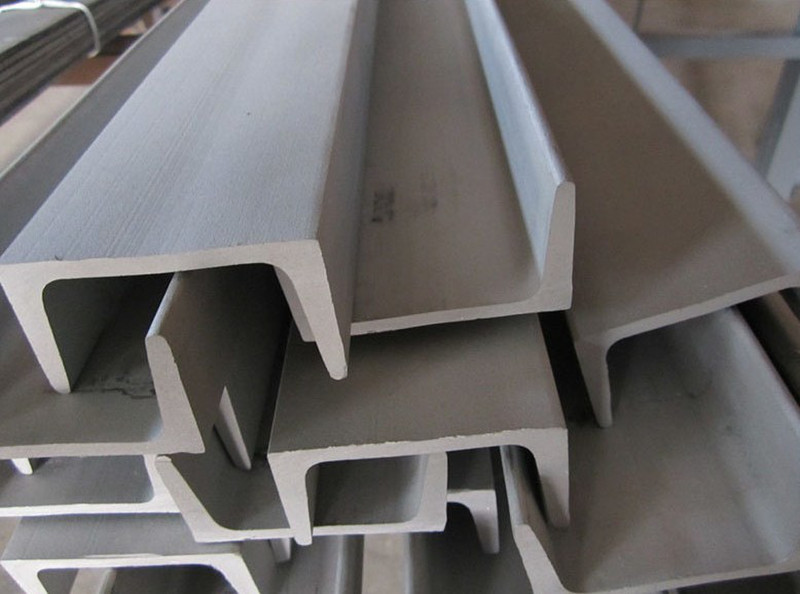

The channel produced by the standard according to EN 10279, and is divided into the following types:

regular UNP/C with sizes from 50 mm to 400 mm;

parallelnyy UPE with sizes from 80 mm to 400 mm;

economical E with sizes from 80 mm to 200 mm.

In addition to the standard applications of steel channel construction to increase rigidity and stability of structures, due to its ability to withstand large axial loads and bending loads, meet interesting application of this kind of metal. For example, the channel allows you to mount the perforated metal construction without welding, which significantly reduces installation time. For all channels the high shelves and wide distance between them. For installation of storage racks are better channels with less room, since the weight of steel channel, causing the weight of the rack, should not be large. It also occurs using channel for reinforcement of walls, forming the ceiling. Use channels and as a guide of the lifting device that has the catcher's spontaneous braking. Another application area - ramps for wheelchairs and trolleys, made of steel channel. For the interior channels is used as a frame for laying of high voltage cables as well as pipelines and water pipelines. Scope of channels depends not only on size but also on the grade of steel from which they are produced. In particular, steel bars S355J2+N (or 17G1S, 09G2S) it is made of low alloy steel, which is resistant to low temperatures (to -70°C), due to the small content of carbon and manganese. This channel is rational to apply in the environment in which other steels become brittle. In particular, using channel S355J2+N (or 17G1S, 09G2S) is justified in the far North. His welding is performed without preheating and subsequent heat treatment.

-

Payment Methods

We accept: